Since the inception of J Tech Photonics, we strive to create standard solutions using the best technologies in electronics and optics. We also have been working behind the scenes doing custom projects for our customers. Our partnerships have created some amazing products and we will continue to devote energy into helping our customers succeed.

Our Services

- Product development from customer specification to final manufacturing and marketing.

- Consulting for engineering and product management.

- Contract work for specific needs including engineering system design, circuit board design, system integration and customer specific needs.

Our Capabilities

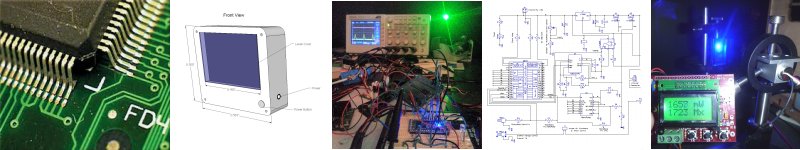

- Engineering design, system design, and system integration.

- Electrical circuit board design with schematic capture, simulation, and layout.

- Diptrace schematic and layout and spice simulation tools.

- Optics design and simulation.

- Mechanical 3D modeling tools.

- Embedded processing with ARM Cortex M3 microcontrollers.

- USB 2.0 design and implementation.

- FPGA Design with Xilinx products and Verilog language.

- Software development with MS Visual Studio C++, C#

- 3D printing capabilities for mechanical rapid prototyping.

- Electrical prototyping and debug lab.

- Optics prototyping lab.

- In house circuit board manufacturing capabilities for SMT assembly.

- Laser processing tool for solder stencil creation.

Highlighted Projects

Remote wireless thermal detection and live video integration in fire apparatus

Project: Add integrated live video and thermal detection capability to the Gradall SERV (www.gradallserv.com) remote firefighting vehicle.

The Gradall SERV vehicle and the 5th man fire head is a impressive and revolutionary way to fight fires. Eagle fire Equipment came to J Tech Photonics with the task of integrating a solution into the head of the piercing fire head with some very difficult specifications. The camera and thermal detector could be no more than 1 inch in diameter, the electronics could be no more than 3″x3″, it needed to be battery operated for more than 10 hours of operation, detect 1600 degrees F temperature, capture live video, wirelessly communicate, have a thermal detection range of 1600 degrees fahrenheit and withstand environmental impact of greater than 2 G’s. The team took the specifications and came up with an design integrating a small tube camera and a industrial temperature monitor coupled with custom embedded electronics for processing and overlaying information on the video feed and sending it out via wireless RF to a display. Size, power, and environmental concerns were all met and the new electronics were integrated into the fire head. Now, the firefighters have remote thermal video capability to accurately detect and verify where “hot spots” are in a building before punching through with the piercing nozzle.