So we have been holding off here at J Tech Photonics on offering the newer high power diodes in the 9mm package. Why you ask? Mostly just because they come from very expensive sources and the price per diode was over the budget of many of our customers. We also wanted to make sure that these diodes perform better than the existing 1.7W 5.6mm lasers we already have in our kits.

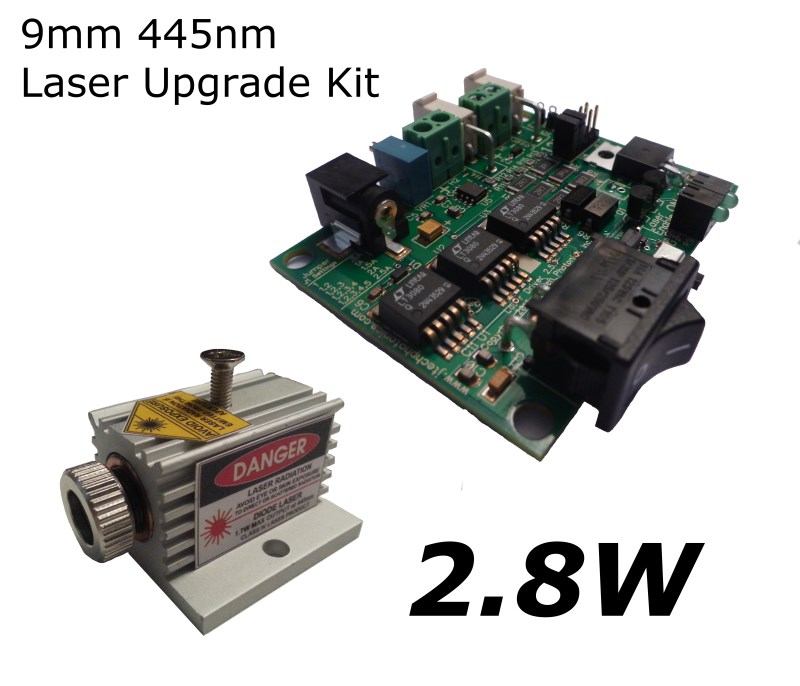

We are offering two versions of this new diode:

- 2.2W version with a standard 3 element coated glass lens

- 2.8W version with a high efficiency G2 coated glass lens

Output Power

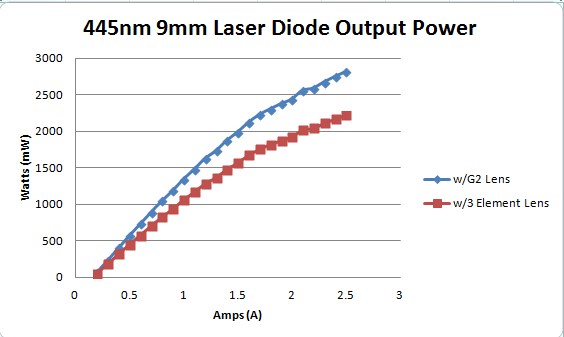

As for power, these new diodes can run with more amps for longer duration. We recommend the 5.6mm diodes run at 1W to keep them within the normal operating range. These new diodes can run between 1.3amps to 1.7amps to keep within the operating range of the laser diode. That means 1.3W to 1.7W of output power for the 3 element lens version and 1.6W to 2.2W with the G2 lens version. We have run these up to 2.5amps which will give it the maximum output power. Some people will run it higher and achieve over 3W with these diodes, but we believe that you are risking blowing up a very nice laser by going higher than 2.5amps. Actually, anything above 1.7amps should only be done for very short amount of time as you are really pushing the laser to it’s thermal limits.

Here is a graph of the output power of these new diodes:

As you can see the output power stays very linear up to 1.7amps and then slightly turns down. This linear region is where the diode is in it’s best operation for long term use. You can also notice the extra efficiency that the G2 lens provides over the 3 element lens.

Spot Size

Considering the new diodes are in a 9mm package, the laser die is also a bit bigger. This means that the spot size is going to be just slightly larger than what you can get with the older 5.6mm 1.7W lasers. The spot size is going to be more in the range of 0.01″ or 10mil instead of the 0.006″ or 6mil that the 5.6mm lasers can achieve. This is not going to effect cutting of materials that much and will only effect engraving when it is down in the 6 point font area. Engraving anything larger will be much, much faster due to the extra power at the work surface.

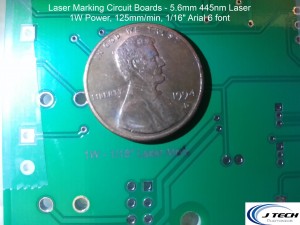

Here is a picture of engraving on circuit boards we did with both the 9mm laser and the 5.6mm laser. You can see the 9mm laser has a thicker, less defined character than the 5.6mm laser has. This is of course only happens when you are engraving very, very small objects or pictures.

The first picture is with the 5.6mm laser and the second is the 9mm laser. The difference would be that you can crank up the power in the 9mm laser and do this mark at 250mm/min versus the 125mm/min of the 5.6mm.

What About Cutting?

Yes, this baby can cut. It still will be similar to the 1.7W diodes abilities, but it will be much faster. We just tried to cut 1/16″ birch plywood with it and got through it after about 10 passes at 100mm/min, but I would not call it really a success. The best things this can cut are still porous woods like balsa and basswood, different kinds of foam, paper and cardboards, thin plastics, and other lightweight applications.

Easy Mounting and No Maintenance!

So overall, for just over a couple of hundred dollars, it still is a great start to get into laser processing without the hassle of CO2 and water cooling! We are working here at J Tech Photonics to get more and more power so we can one day offer a diode laser solution that can go head to head with the CO2 laser with it’s cutting ability.

Want to Upgrade Your Existing Kit?

All of the kits we have shipped for the 1.7W will also work with the new 9mm lasers. If you are interested in upgrading, we are offering a special promotional discount of 20% off the new laser for existing customers. Just email us at [email protected] for the discount code today!