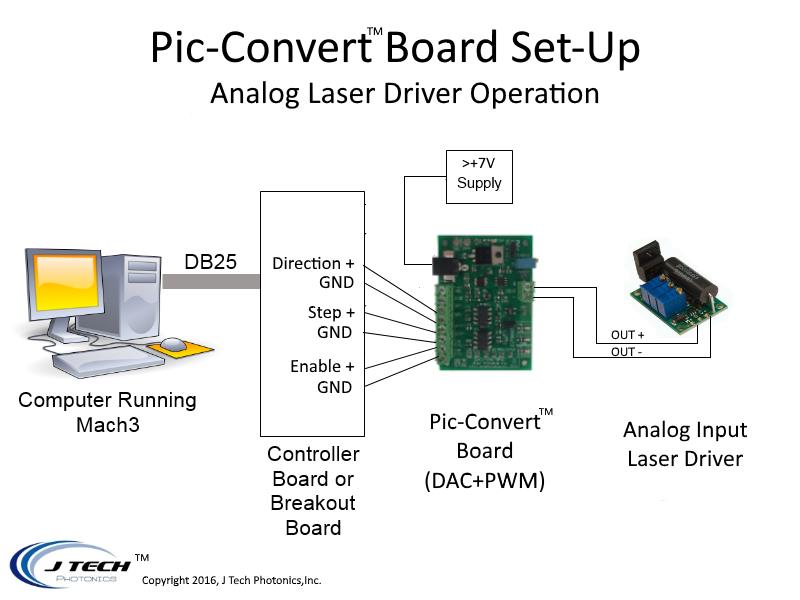

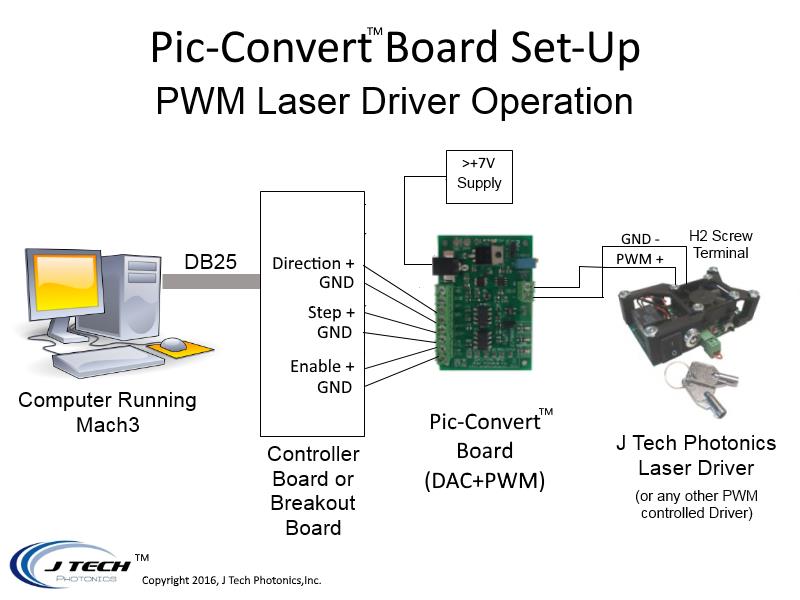

We have been working with Jeff and John at picengrave.com to develop this solution for use with their picengrave software for laser image engraving. This board uses the STEP and DIRECTION signals from a spare axis to output an analog or PWM signal to a laser driver for laser power control. This allows software controlled CNC machines (like Mach3) to adjust the laser power on the fly for image engraving applications.

This is the 5th generation of this board. We have been extensively testing with beta customers for the last 9 months to get the best industrial solution possible for engraving images with mach 3. We have made all of the inputs isolated and designed the board to have minimal noise which can cause the counter to loose steps. This version is now the most reliable and easy to set up, making it easier to generate images from mach 3. However, this is not the easiest process to accomplish. You must have a general understanding of how to set up mach 3 and the board to get it to work. Please read the manual before you purchase this product. We will offer support but we can’t fly out to get it all to work on your machine.

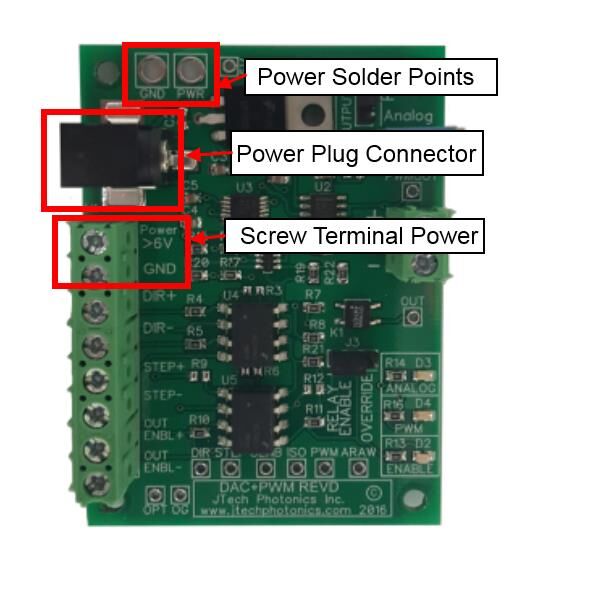

You can get it with a North America power adapter or an OEM power cord that you can attach to a power supply.

Features

- Convert Step and Direction signals into analog output or PWM output for laser drivers.

- Isolated inputs to work on many controllers

- Included power adapter and other power options.

- PWM output for PWM modulated drivers

- Analog output for analog modulated drivers

- Output Enable Relay to control output with M03 command

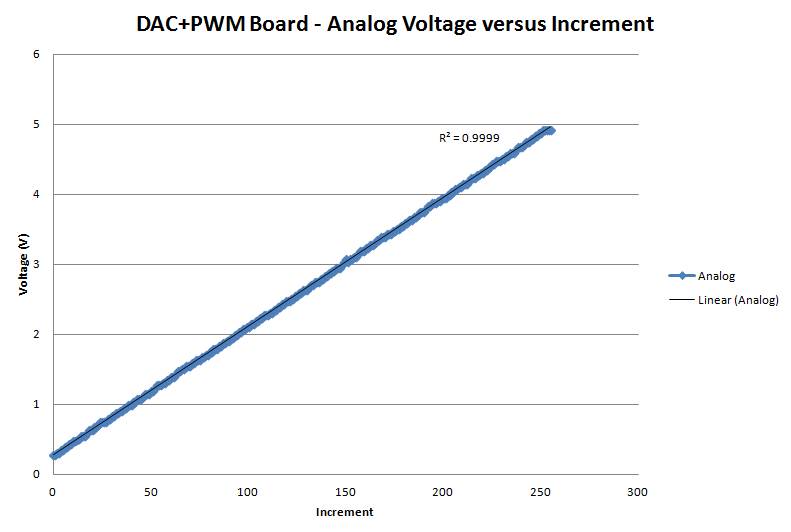

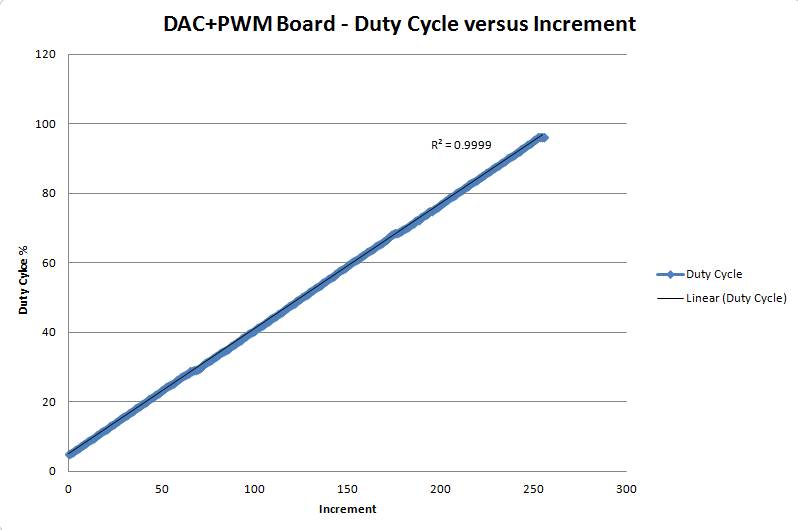

- Highly linear output for both PWM Duty Cycle and Analog Voltage Output Operation

Specifications

- Analog Output voltage maximum adjustable from 3.3V to 4.95V

- Analog Output Range: 0.1V to 4.9V

- PWM Output Frequency: 1KHz

- PWM Output Min: 2%

- PWM Output Max: 98%

Product Manual

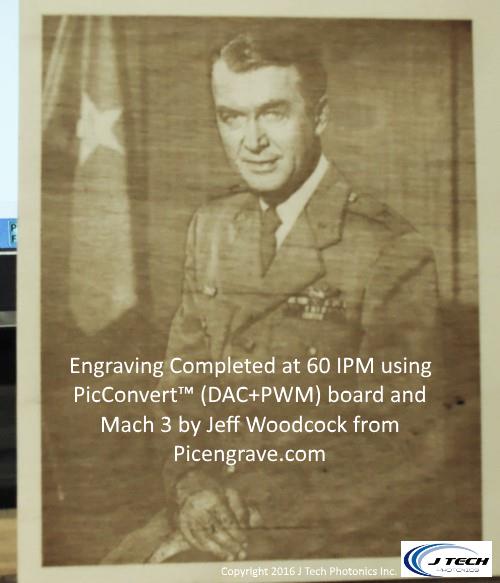

Example Engraving

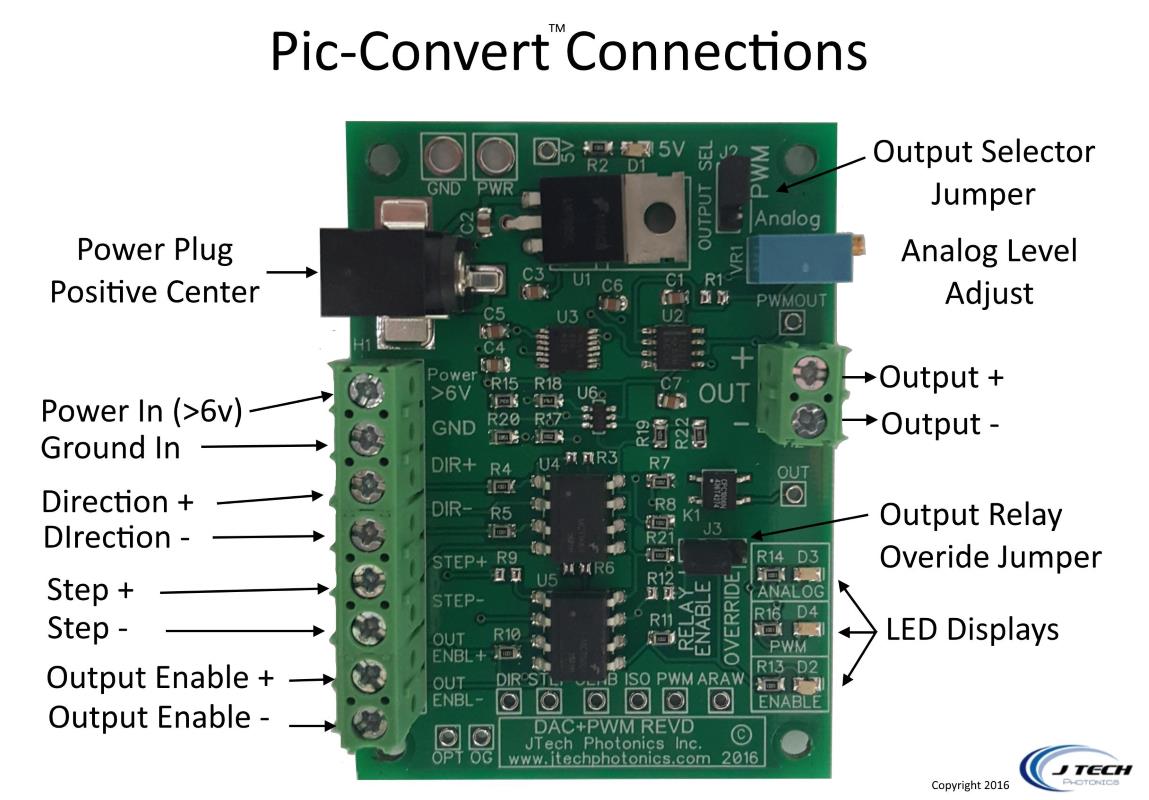

Connection Overview

Setup For PWM Operation

Set-Up for Analog Operation

Reviews

There are no reviews yet.